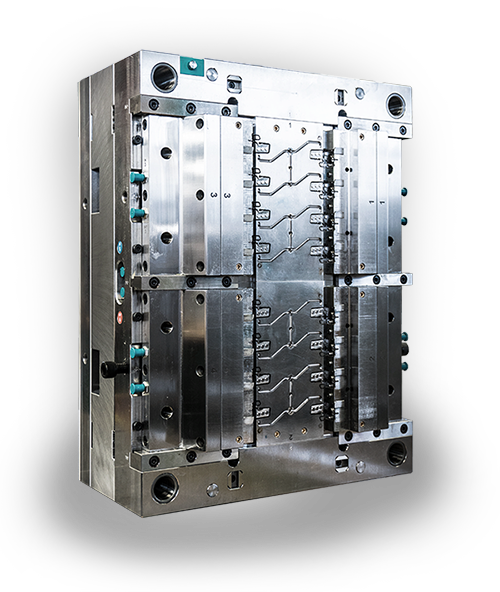

Production of molds and parts

Our production program includes series, two-component, etched and prototype molds for plastics with customized construction. We also produce individual parts of the molds.

We use the normals of companies: Meusburger, HASCO, DME and hot systems from: INCOE, Synventive, Husky, DME, HASCO, Ewikon, Gunther. However, other norms may be used as well.

The maximum mold size is limited by our machine park. It is a size of 1000 x 700 and a weight of 5000 kg.

- Production of CNC parts by milling

- Sparking and wire cutting

- Laser 3D machining

- Laser marking and engraving

- Repair of molds and individual part

Molds designing

The design and construction is of our own. We use Solidworks CAD software with the support for SolidCAM CAM software.

2D and 3D laser engraving

Laser and its powerful software allows machining of 3D models, structures, contours and various surfaces. It can be used where the use of classical machining technology would be complicated or technically demanding, as is the case with the fine 3D shapes.

- 3D engraving and machining – lots of machined materials

- Production of cliché for printing by tampoprint

- Description of machine parts (tools, tools, mold inserts, labels, scales, gauges, etc.)